Distribution centers and e-commerce operations face unprecedented challenges in today’s fast-paced market. High-volume order processing, diverse product sizes, and rapid shipment requirements create significant operational pressures. Every minute of downtime can cost thousands of dollars in lost productivity, making efficient material handling systems crucial for maintaining a competitive advantage.

Modern facilities often process hundreds or even thousands of orders per hour, requiring equipment that can handle anything, from small packages to bulk items, while maintaining consistent speed and accuracy. This dynamic environment demands conveyor solutions that can adapt to changing needs and integrate with automation systems.

Key Takeaways

Today’s e-commerce facilities face unprecedented challenges with high-volume order processing, diverse product sizes, and rapid shipment requirements. Every minute of downtime can cost thousands in lost productivity, making efficient material handling systems crucial for maintaining a competitive advantage.

To address these challenges, distribution centers should:

- Implement modular conveyor systems that maximize vertical space utilization to ensure minimal footprints while maintaining operational efficiency

- Select solutions capable of belt speeds between 300-600 feet per minute to meet same-day and next-day delivery expectations

- Prioritize flexible designs allowing for rapid reconfiguration, easy expansion, and integration with automation technologies

- Focus on maintenance-friendly features like quick belt change designs, tool-free access, and easy monitoring system integration

Advanced solutions worth considering include modular belt technology for handling diverse products, flexible chain systems for complex layouts, and precision move conveyor systems for automated sorting operations. These should be paired with intelligent controls for real-time flow management, data integration, and automation coordination.

When evaluating new conveyor systems, calculate ROI beyond the initial purchase price by considering labor savings, throughput increases, reduced product damage, energy efficiency, and improved space utilization.

Questions? Don’t hesitate to contact us for custom conveyor solutions.

Key Challenges in Distribution Center Operations

Space Optimization

Warehouse space comes at a premium, especially in urban areas near customer bases. Effective material handling solutions must maximize vertical space utilization while maintaining an efficient footprint. Low-profile conveyor designs can fit into tight spaces, allowing for integration with existing equipment and workstations.

Throughput Efficiency

Meeting same-day and next-day delivery expectations requires maximizing the number of items processed per hour. Conveyor systems must support high speeds while maintaining precision, especially at transfer points and sorting locations. Belt speeds of 300-600 feet per minute are increasingly necessary for high-volume operations.

System Flexibility

Distribution requirements change frequently based on season, product mix, and business growth. Modern conveyor systems need modular designs that allow for:

- Rapid reconfiguration for different product flows

- Easy expansion as volume increases

- Integration with automation technologies

- Adaptation to varying product sizes and weights

Maintenance Requirements

Minimizing downtime is essential in high-volume operations. Key maintenance considerations include:

- Quick belt change designs (ideally under 5 minutes)

- Tool-free maintenance access

- Seamless integration with proactive monitoring systems

- Strategic parts inventory management compatibility

- Reliable tracking mechanisms that reduce adjustment needs

Advanced Conveyor Solutions for E-Commerce Challenges

Modular Belt Technology

Modular belt conveyors provide significant advantages for distribution operations handling diverse products:

- Easy maintenance with quick-release belt designs

- Extended belt life due to high-quality materials

- Various material options to suit diverse applications

- Flexible configurations for complex production layouts

- Ability to handle small, delicate items and heavy packages on the same system

View Dorner Modular Belt Conveyors

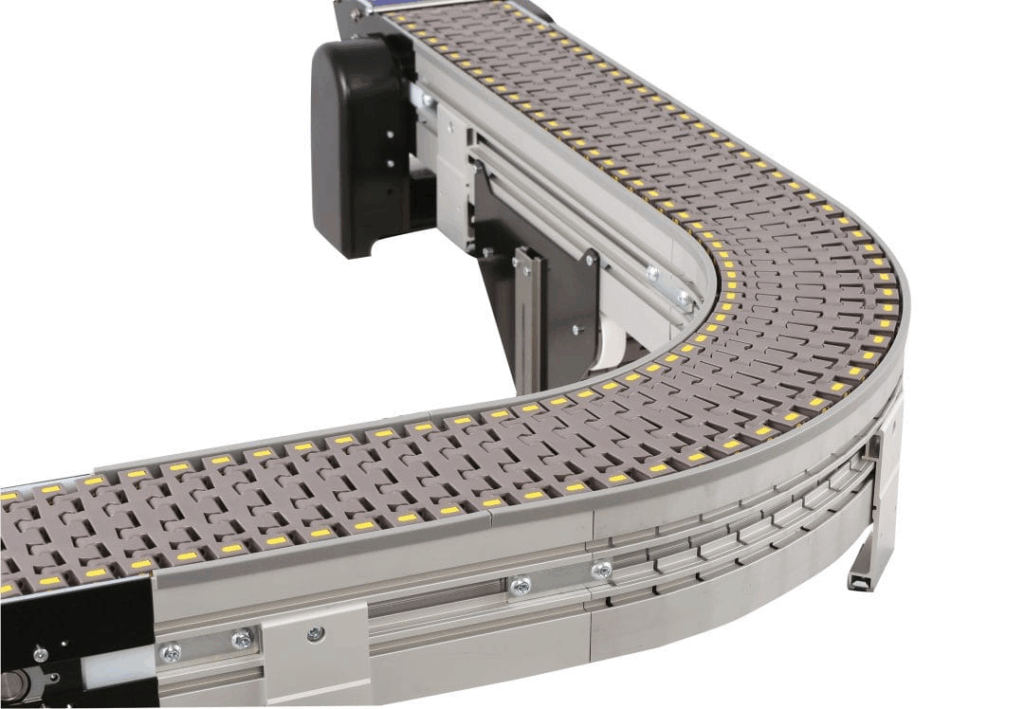

Flexible Chain Systems

Distribution centers with complex layouts benefit from flexible chain conveyor systems that offer:

- Multiple turns and inclines within a single line

- Low-profile design ideal for tight spaces

- Easy integration with controls and sensors

- Ability to handle products of varying sizes without adjustment

- Economic installation in complex production environments

View Dorner Flexible Chain Conveyors

Precision HandlingSystems

For automated sorting operations, precision move conveyors deliver exceptional accuracy crucial for:

- Robotic pick-and-place integration

- Automated quality inspection

- Barcode and RFID scanning stations

- Precise product positioning for packaging

- Synchronized operations with other equipment

View Dorner Precision Move Conveyors

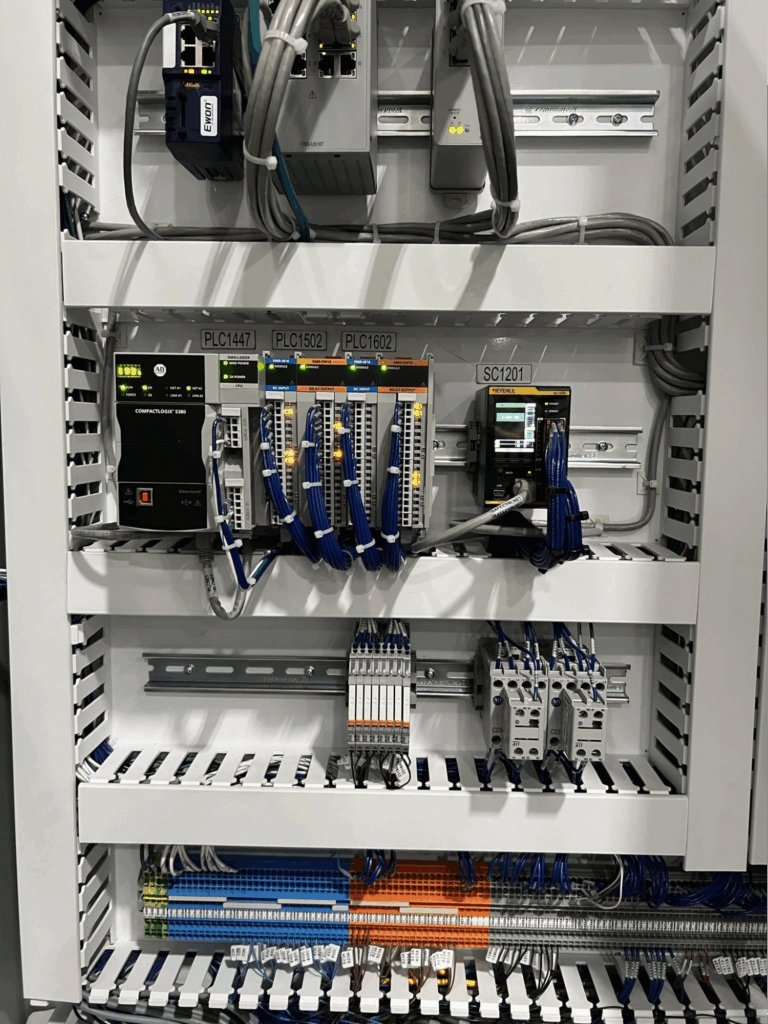

Intelligent Controls for Distribution Efficiency

Modern conveyor systems incorporate advanced control technologies that transform material handling capabilities:

Real-Time Flow Management

- Dynamic speed control based on system load

- Automatic zone management to prevent product collisions

- Accumulation control that prevents backups

- Load balancing across multiple lines

Data Integration

- Connection with warehouse management systems

- Real-time throughput monitoring

- Predictive maintenance alerts

- Performance analytics for continuous improvement

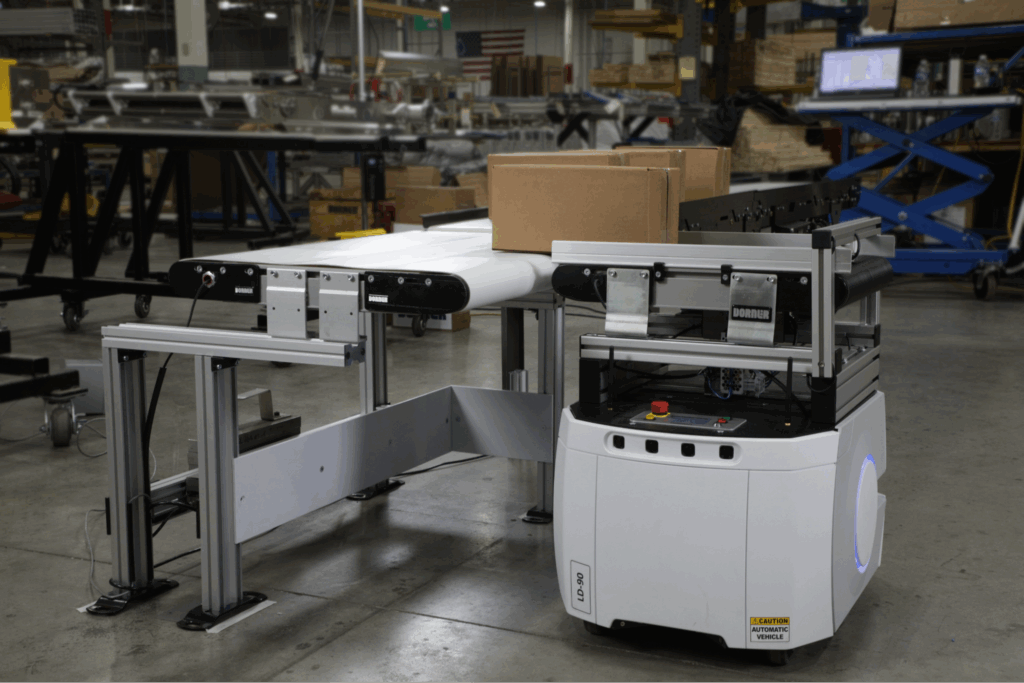

Automation Integration

- Seamless connection with robotic systems

- Coordination with autonomous mobile robots (AMRs)

- Integration with picking technologies

- Communication with packaging equipment

Space-Saving Design Innovations

Maximizing available space is critical for distribution efficiency. Modern conveyor designs address this need through:

Vertical Transport Solutions

Spiral and helical designs efficiently move products between levels while minimizing footprint, dramatically increasing throughput capacity per square foot of warehouse space.

Compact Drive Technologies

Internal motor designs eliminate external motors and gearboxes, reducing overall width requirements and allowing conveyors to fit in tighter spaces.

Z-Frame Configurations

Elevation changes within a single conveyor eliminate the need for multiple conveyors, reducing complexity and maximizing floor space efficiency.

Maintenance Optimization Strategies

Preventing downtime requires a strategic approach to conveyor maintenance:

Proactive Monitoring

Modern systems include belt tracking indicators, drive component monitoring, and predictive analytics that identify potential failures before they occur.

Strategic Parts Management

Maintaining critical components inventory based on failure analysis ensures parts are available when needed, minimizing downtime during unexpected repairs.

Simplified Component Design

Quick-change belt systems, tool-free access points, and modular components dramatically reduce maintenance time requirements compared to legacy systems.

Industry-Specific Applications

E-Commerce Order Fulfillment

Distribution centers focused on direct-to-consumer shipping benefit from specialized conveyor configurations designed for:

- High-volume order sortation using diverters and pushers

- Multi-SKU product handling with advanced tracking

- Returns processing operations

- Last-mile preparation

Parcel Handling

Systems designed specifically for varying package sizes can incorporate:

- Dynamic width adjustment

- Weight-based sorting capabilities

- Barcode scanning integration

- High-speed merge points

Cross-Docking Operations

Facilities focused on rapid transfer from inbound to outbound shipping require:

- High-speed straight runs

- Efficient merge points

- Simple control systems

- Durable construction for continuous operation

Implementation Considerations

System Assessment

Before selecting conveyor systems, operations should evaluate:

- Current and projected throughput requirements

- Product mix and handling characteristics

- Available floor and vertical space

- Integration requirements with existing systems

- Growth projections and flexibility needs

Installation Planning

Minimizing disruption during implementation requires careful planning:

- Phased implementation approach

- After-hours installation scheduling

- Temporary manual workflows during transitions

- Training programs for operations and maintenance staff

- Testing protocols before full deployment

Return on Investment Factors

When calculating ROI for conveyor systems, consider these factors beyond the initial purchase price:

- Labor savings through automated material movement

- Throughput increases and associated revenue gains

- Reduced product damage from consistent handling

- Energy efficiency compared to legacy systems

- Maintenance requirements over system lifetime

- Space utilization improvements

Modern e-commerce and distribution operations require intelligent material handling solutions that deliver reliability, flexibility, and efficiency in today’s competitive logistics environment. From compact systems for small items to heavy-duty industrial conveyors for large parcels, the right conveyor technology can transform operational capabilities and support growth strategies.

By focusing on modular designs, intelligent controls, and preventative maintenance, distribution centers can achieve the throughput, accuracy, and flexibility needed to meet evolving customer expectations for rapid delivery while controlling operational costs.

FAQs

What types of conveyor belts work best for different distribution applications?

Distribution centers typically use three main belt types: fabric belts for smooth transfer of small items, modular belts for versatility and easy maintenance, and flexible chain belts for complex layouts with multiple turns. The choice depends on specific requirements like product weight, size consistency, and handling needs. Fabric belts work well for lightweight sorting, while modular belts handle heavier loads with longer service life. Flexible chain offers maximum layout adaptability for complex spaces.

What load capacities should distribution centers consider when selecting conveyors?

Distribution operations should evaluate their heaviest regular items and maximum peak loads when selecting conveyor systems. Light-duty systems handling up to 15 lbs per item work for small parcel sorting, while medium-duty conveyors supporting 120-150 lbs accommodate most standard packages. Heavy-duty operations with loads up to 1,000 lbs are necessary for bulk handling and pallet movement. Always factor in accumulation scenarios where multiple items might create concentrated weight zones.

How quickly can modern conveyor systems be installed in an active distribution center?

Modern modular conveyor systems are designed for rapid deployment, with many systems shipping pre-assembled in sections that connect quickly. Standard configurations can often be installed within 1-2 days for basic runs, while complex systems typically require 1-3 weeks depending on integration requirements. The most advanced systems feature tool-free assembly and pre-configured controls that minimize downtime. Many facilities implement changes during weekend periods to minimize operational disruption.

What maintenance is required for distribution center conveyor systems?

Modern conveyor systems feature significantly reduced maintenance requirements compared to legacy equipment. Key maintenance typically includes monthly inspection of tracking systems, quarterly check of drive components, and semi-annual lubrication of limited points. Well-designed systems include sealed bearings that eliminate regular lubrication needs and precision tracking mechanisms that maintain alignment. Belt systems with quick-change capabilities allow for replacement in under 5 minutes, minimizing downtime during eventual wear replacement.

How do conveyor systems ensure compliance with industry safety standards?

Distribution conveyors incorporate multiple safety features, including emergency stop systems, pinch point protection, and controlled startup warnings. All systems should comply with OSHA and ANSI standards for industrial equipment. Advanced systems include safety guarding, anti-restart protection after power loss, and integrated light curtains at critical junctures. Regular safety audits should be conducted to ensure ongoing compliance with standards, especially when reconfiguring systems or integrating new components.

What customization options should distribution centers consider for specific applications?

Distribution operations should evaluate several key customization factors: belt surfaces appropriate for product characteristics, guide rails for product containment, divert mechanisms for sorting operations, variable speed capabilities for throughput management, and control integration with warehouse management systems. Custom widths and configurations may be necessary to fit existing facility layouts. Special considerations for electronics or sensitive items might include static-dissipative belting or cushioned surfaces for fragile products.

What support services are most valuable after conveyor installation?

The most valuable post-installation support includes preventive maintenance programs, rapid parts availability, technical training for maintenance staff, and emergency repair services. Facilities should prioritize providers with extensive parts inventory and quick shipping capabilities to minimize potential downtime. Digital documentation and troubleshooting guides improve in-house maintenance capabilities. Remote monitoring and diagnostic services allow for proactive maintenance scheduling before failures occur, dramatically reducing unplanned downtime.

How can conveyor systems improve distribution center efficiency?

Conveyor systems enhance efficiency through several mechanisms: eliminating manual transport labor, maintaining consistent processing speeds, enabling precise sortation, and providing accumulation zones that prevent bottlenecks. High-speed capabilities maximize throughput, while precision controls ensure accurate sortation and packing operations. Integration with automation systems creates seamless workflows that dramatically increase items processed per labor hour. Modern systems also reduce product damage through consistent handling, improving customer satisfaction and reducing returns processing costs.